GTECHs offers analysis and simulations that ensure the quality and functionality of the new designs or changes in existing products.

We specialize in different types of finite element analyses that allow you to make decisions based on numeric methods that approximate your prototype’s behaviors for new products and reduce costs in improvement processes for your existing products.

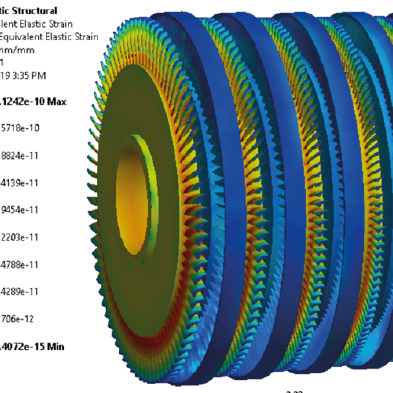

Our finite element analysis brings solutions to structural, thermal and fluid mechanic issues, aiding in cost and prototyping time reductions, providing manufacturing and new product design support.

Based on our wide experience in different product development areas for high technology industry sectors, our finite element analysis services are a valuable resource in product development stages.

Contact us to request a customized plan for your project needs.

Analysis types and practical applications

-

- Fluid analysis Internal, external: compressible at high speeds or rotational fluid behaviors, pressure changes including turbulence or laminar fluids.

- Mechanical and structural analysis: Mechanical effects of vibrations, shock, focalized loads, fatigue. Geometry contacts and material plasticity with linear or non-linear properties. Natural frequency analysis, including random base and harmonics.

Thermal analysis - Dissipation by conduction or convection: phase changes, external and internal heat sources.

GTECHs eliminates simulation limitations caused by hardware and license costs requirements of local use platforms, by replacing them with our online analysis portfolio.

Do you have a problem and don’t know how to solve it? Contact us to schedule an advisory session.