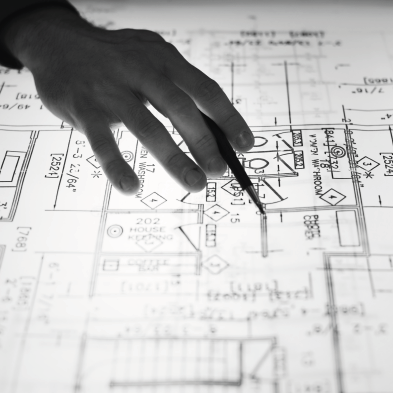

Cross Section

This is a destructive technique to cut or ground away excess material on a portion of a test sample to expose internal planes to be analyzed. This method is commonly used for research, manufacturing quality assurance and failure analysis. Learn about the effects of your soldering alloy, reflow profile, flux chemistry, product life and product classification.

GTECHs offers you knowledgeable support with ample experience to help you assess cross section analysis method applications. From sample preparation to results analysis, our expert team is the solution.

One of the most common applications in manufacturing QA is on solder joints between components and PWBs/PCBs. Features of interest to be analyzed using this technique can be semiconductors’ metal and dielectric layers in nanometric scale. This test procedure allows analyzing microscopic features, including the solder filling in a plated through hole assemblies.

Do you have a problem and don’t know how to solve it? Contact us to schedule an advisory session.

X-Ray Inspection

GTECHs X-ray inspection technology services, usually referred to as Automated X-ray Inspection (AXI), grants you access to a technology used to inspect the hidden features of target objects or products. Nowadays, it is widely used in a variety of industries, such as medical, industrial control, and aerospace.

GTECHs AXI services are commonly used in the manufacturing industry as part of the PCB assembly quality assurance process. It is a useful tool for the quality-oriented electronics manufacturer. It can be used on daily validation on ball grid array component lots.

Our team of experts gives you access to X-Ray non-destructive inspection that is required if there is no system already mounted on your production line. GTECHs consultants are prepared for analyzing X-ray imaging and provide a full findings report, as well as offering you root cause analysis and possible corrective actions.

Do you have a problem and don’t know how to solve it? Contact us to schedule an advisory session.