Tolerance Stackup

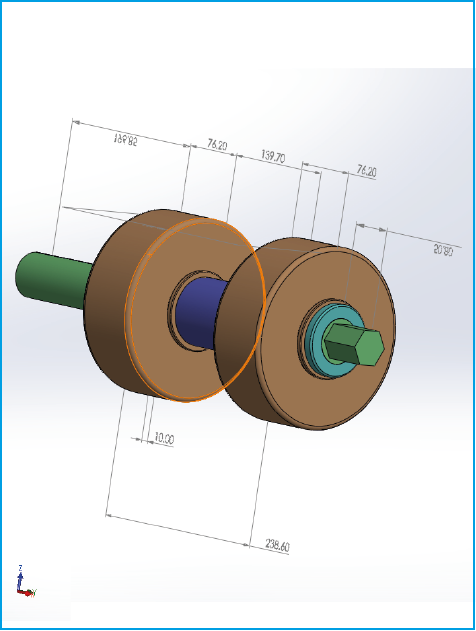

Also known as tolerance stacks, it is a mathematical and statistical problem solving method for variation accumulation allowed by the specified dimensions and tolerances in a design. It is useful in establishing and optimizing tolerances, an easy solution to make sure all parts in an assembly fit together. It is a useful design evaluation tool, that can also be helpful in troubleshooting manufacturing issues.

Tolerance stackups provide worst-case maximum or minimum values of dimensions and tolerances between two parts and it is used to calculate either a clearance or an interference. This analysis also provides statistical values based on the absolute arithmetic calculation combined with a statistical methods (such as Root Sum Square aka RSS, or Monte-Carlo) for establishing likelihood of obtaining the maximum and minimum values.

Our experts provide consulting and orientation on any specific tolerance stackup topics. GTECHs’ consultants have years of experience performing this type of analysis, and are ready to help you improve on your assembly designs as well as solving your manufacturing issues.

Do you have a problem and don’t know how to solve it? Contact us to schedule an advisory session.